NEWCOBOND® Best Quality Mirror Aluminum Composite Panel ACP for Design

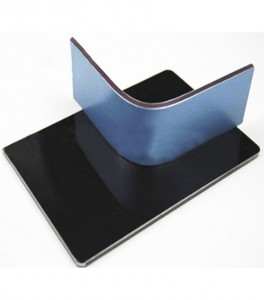

From the perspective of appearance decoration effect, the NWECOBOND®core advantage of mirror aluminum composite panels lies in its excellent visual expression. Its surface has been specially polished to form a mirror-like high-definition reflection effect, which can clearly reflect the surrounding environment and break the sense of space limitation. In commercial space design, such as shopping mall exhibition halls, hotel lobbies, etc., using mirrored aluminum-plastic panels as wall or ceiling decoration can expand the visual space with the help of reflective properties, making the originally narrow area appear more open and transparent. Mirror aluminum composite panels can be cut, bent, and grooved according to design requirements, and can be made into various shapes such as arcs and special shapes to meet complex decoration needs, such as curved booths for shopping mall counters, special-shaped background walls in homes, etc.

At the same time, with lighting design, it can also create a bright and modern atmosphere and enhance the overall decoration grade. In home decoration, applying it to kitchen backsplash (oil-proof wall) or bathroom wall not only makes the space brighter and tidier, but also reduces dark corners by reflecting light, allowing small apartments to have an "expansion" effect. In addition, the mirror aluminum-plastic panels come in a wide range of color options. In addition to the classic silver mirror, various tones such as gold, black, and champagne can also be customized to meet the design needs of different styles. Whether it is modern simplicity, light luxury or industrial style, it can be perfectly adapted. We welcome OEM and customization request; regardless of the standard or color you like, NEWCOBOND® will give an appropriate solution for your projects. They are extremely lightweight and study, making them ideal for environments where safety is a concern.

STRUCTURE

ADVANTAGES

ENVIRONMENTAL FRIENDLY

NEWCOBOND used recyclable PE materials that imported from Japan and Korea, composite them with pure AA1100 aluminum, it’s totally non-toxic and friendly to environment.

EASY PROCESSING

NEWCOBOND ACP has good strength and flexibility, it’s easy to transform, cut, fold,drill, curve and install them.

WEATHER-RESISTANT

Surface treatment with high-grade ultraviolet-resistant polyester paint (ECCA) request, guarantee 8-10 years; if use the KYNAR 500 PVDF paint, guaranteed 15-20 years.

OEM SERVICE

NEWCOBOND can supply OEM service, we can customize size and colors for clients. All RAL colors and PANTONE colors are available

DATA

| Aluminum Alloy | AA1100 |

| Aluminum Skin | 0.18-0.50mm |

| Panel Length | 2440mm 3050mm 4050mm 5000mm |

| Panel Width | 1220mm 1250mm 1500mm |

| Panel Thickness | 4mm 5mm 6mm |

| Surface treatment | PE / PVDF |

| Colors | All Pantone & Ral Standard Colors |

| Customization of size and color | Available |

| Item | Standard | Result |

| Coating Thickness | PE≥16um | 30um |

| Surface pencil hardness | ≥HB | ≥16H |

| Coating Flexibility | ≥3T | 3T |

| Color Difference | ∆E≤2.0 | ∆E<1.6 |

| Impact Resistance | 20Kg.cm impact -paint no split for panel | No Split |

| Abrasion Resistance | ≥5L/um | 5L/um |

| Chemical Resistance | 2%HCI or 2%NaOH test in 24hours-No Change | No Change |

| Coating Adhesion | ≥1grade for 10*10mm2 gridding test | 1grade |

| Peeling Strength | Average ≥5N/mm of 180oC peel off for panel with 0.21mm alu.skin | 9N/mm |

| Bending Strength | ≥100Mpa | 130Mpa |

| Bending Elastic Modulus | ≥2.0*104MPa | 2.0*104MPa |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Temperature Resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropped≤10% | Change of glossy only.No paint peel off |

| Hydrochloric Acid Resistance | No change | No change |

| Nitric Acid Resistance | No Abnormity ΔE≤5 | ΔE4.5 |

| Oil Resistance | No change | No change |

| Solvent Resistance | No base exposed | No base exposed |

Related PRODUCTS

-

Whatsapp

-

Whatsapp

WhatsApp

-

Top