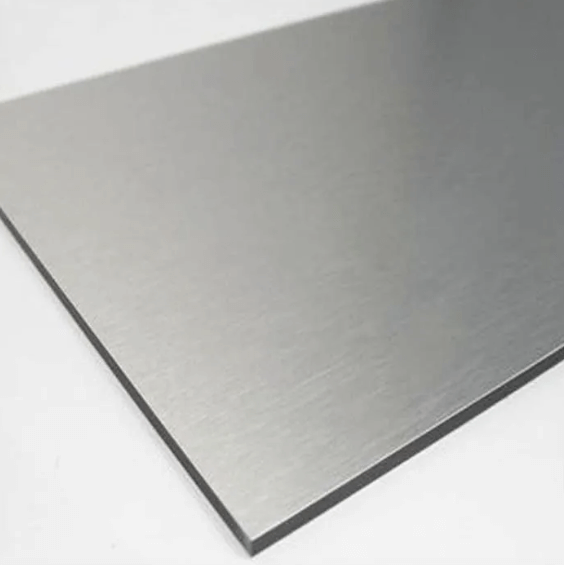

NEWCOBOND® PE PVDF Bushed Color Aluminum Composite Panel for External Cladding

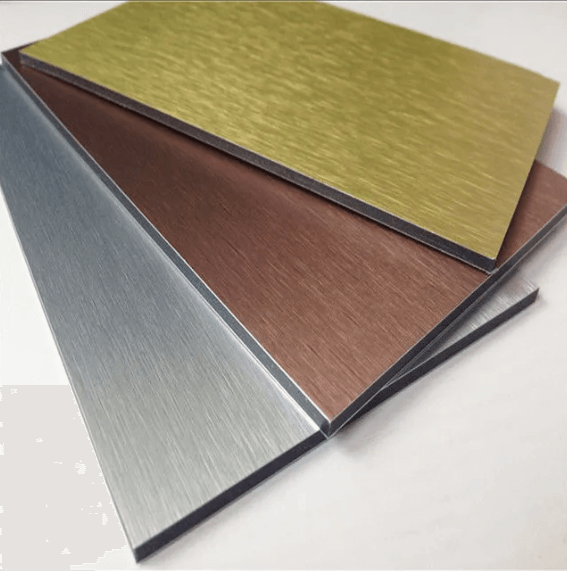

This texture feature makes it easy to adapt to a variety of design styles: in modern minimalist-style homes, used for TV background walls or entrance panels, the light gray brushed texture can enhance the simplicity and neatness of the space; in industrial-style commercial spaces (such as cafes, fashion brand stores) in high-end office buildings or hotel lobbies, champagne gold or rose gold brushed styles can enhance the light luxury texture of the space, replacing traditional stainless steel materials to create a warmer visual experience. In addition, the brushed texture also has the practical feature of "hiding flaws" - compared with smooth mirror materials, fine scratches or fingerprints are more difficult to detect on the brushed texture. In daily use, it can maintain a tidy appearance without frequent cleaning, which is especially suitable for public areas with high traffic or families with children.

The surface of the brushed aluminum composite panel has a fine, uniform filamentous texture, and there is a suitable unevenness to the touch. It is not as dazzling as mirror stainless steel, but exudes a low-key, restrained, premium matte metallic sheen. This soft and textured luster can significantly elevate a building. These colors, combined with brushed textures, not only retain the diversity of colors, but also avoid the bland color plate, with excellent decorative effects. NEWCIBOND aluminum composite panels have excellent fire resistance. The middle part is a flame-retardant PE plastic core material, and the two sides are extremely difficult-to-burn aluminum layers, meeting the fire resistance requirements of building regulations. Aluminum composite panels have a wide range of uses and can be utilized in a variety of settings, including hotels, retail malls, schools, hospitals, home decor, traffic stations, and several other projects. We accept OEM and customization requirements; no matter what standard or color you desire, NEWCOBOND® will provide a satisfactory solution for your projects.

STRUCTURE

ADVANTAGES

ENVIRONMENTAL FRIENDLY

NEWCOBOND used recyclable PE materials that imported from Japan and Korea, composite them with pure AA1100 aluminum, it’s totally non-toxic and friendly to environment.

EASY PROCESSING

NEWCOBOND ACP has good strength and flexibility, it’s easy to transform, cut, fold,drill, curve and install them.

WEATHER-RESISTANT

Surface treatment with high-grade ultraviolet-resistant polyester paint (ECCA) request, guarantee 8-10 years; if use the KYNAR 500 PVDF paint, guaranteed 15-20 years.

OEM SERVICE

NEWCOBOND can supply OEM service, we can customize size and colors for clients. All RAL colors and PANTONE colors are available

DATA

| Aluminum Alloy | AA1100 |

| Aluminum Skin | 0.18-0.50mm |

| Panel Length | 2440mm 3050mm 4050mm 5000mm |

| Panel Width | 1220mm 1250mm 1500mm |

| Panel Thickness | 4mm 5mm 6mm |

| Surface treatment | PE / PVDF |

| Colors | All Pantone & Ral Standard Colors |

| Customization of size and color | Available |

| Item | Standard | Result |

| Coating Thickness | PE≥16um | 30um |

| Surface pencil hardness | ≥HB | ≥16H |

| Coating Flexibility | ≥3T | 3T |

| Color Difference | ∆E≤2.0 | ∆E<1.6 |

| Impact Resistance | 20Kg.cm impact -paint no split for panel | No Split |

| Abrasion Resistance | ≥5L/um | 5L/um |

| Chemical Resistance | 2%HCI or 2%NaOH test in 24hours-No Change | No Change |

| Coating Adhesion | ≥1grade for 10*10mm2 gridding test | 1grade |

| Peeling Strength | Average ≥5N/mm of 180oC peel off for panel with 0.21mm alu.skin | 9N/mm |

| Bending Strength | ≥100Mpa | 130Mpa |

| Bending Elastic Modulus | ≥2.0*104MPa | 2.0*104MPa |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Temperature Resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropped≤10% | Change of glossy only.No paint peel off |

| Hydrochloric Acid Resistance | No change | No change |

| Nitric Acid Resistance | No Abnormity ΔE≤5 | ΔE4.5 |

| Oil Resistance | No change | No change |

| Solvent Resistance | No base exposed | No base exposed |

Related PRODUCTS

-

Whatsapp

-

Whatsapp

WhatsApp

-

Top