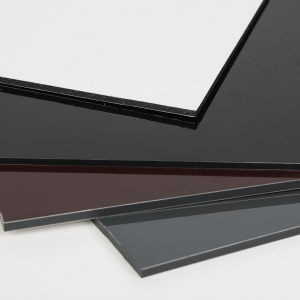

NEWCOBOND® Wood ACM Natural Texture Color ACP

NEWCOBOND® wooden color aluminum composite panels (ACP) have emerged as a top choice in architectural decoration, boasting a unique blend of functionality, aesthetic appeal, and environmental friendliness. Combining the sturdiness of aluminum with the lightness of plastic, these panels are significantly lighter than traditional materials such as natural stone or solid wood—reducing structural load on buildings while simplifying transportation, cutting, and installation. This lightweight nature not only shortens construction timelines but also lowers labor costs, making them a cost-effective solution for various projects.In terms of durability, the aluminum core provides exceptional resistance to moisture, corrosion, and insect infestation, ensuring the panels maintain their integrity even in harsh outdoor conditions or areas with extreme temperature fluctuations. Unlike solid wood, they are less prone to warping, cracking, or fading, offering a long-lasting decorative option that requires minimal maintenance.

From traditional oak and walnut to distinctive vintage patterns, wood grain ACP can aesthetically mimic the complex textures and warm tones of genuine wood without the imperfections or resource shortages that come with actual timber thanks to sophisticated thermal transfer or laminating methods. Their great degree of flexibility also makes it possible to customize them into curved, bending, or irregular shapes, which makes them suitable for a variety of interior and external applications, including walls, ceilings, storefronts, and partitions.Wood grain ACP is completely recyclable, which complies with green building guidelines and lessens the negative effects of deforestation on the environment. Cleaning is made easier by their stain-resistant surface, which can be cleaned with just a moist towel. These panels improve the comfort of any environment with their moderate sound and thermal insulation qualities, which go beyond their utility and aesthetic appeal. Wood grain aluminum composite panels are ideal for public spaces, commercial structures, home remodeling, and more because they skillfully blend sustainability, performance, and aesthetics.

STRUCTURE

ADVANTAGES

ENVIRONMENTAL FRIENDLY

NEWCOBOND used recyclable PE materials that imported from Japan and Korea, composite them with pure AA1100 aluminum, it’s totally non-toxic and friendly to environment.

EASY PROCESSING

NEWCOBOND ACP has good strength and flexibility, it’s easy to transform, cut, fold,drill, curve and install them.

WEATHER-RESISTANT

Surface treatment with high-grade ultraviolet-resistant polyester paint (ECCA) request, guarantee 8-10 years; if use the KYNAR 500 PVDF paint, guaranteed 15-20 years.

OEM SERVICE

NEWCOBOND can supply OEM service, we can customize size and colors for clients. All RAL colors and PANTONE colors are available

DATA

| Aluminum Alloy | AA1100 |

| Aluminum Skin | 0.18-0.50mm |

| Panel Length | 2440mm 3050mm 4050mm 5000mm |

| Panel Width | 1220mm 1250mm 1500mm |

| Panel Thickness | 4mm 5mm 6mm |

| Surface treatment | PE / PVDF |

| Colors | All Pantone & Ral Standard Colors |

| Customization of size and color | Available |

| Item | Standard | Result |

| Coating Thickness | PE≥16um | 30um |

| Surface pencil hardness | ≥HB | ≥16H |

| Coating Flexibility | ≥3T | 3T |

| Color Difference | ∆E≤2.0 | ∆E<1.6 |

| Impact Resistance | 20Kg.cm impact -paint no split for panel | No Split |

| Abrasion Resistance | ≥5L/um | 5L/um |

| Chemical Resistance | 2%HCI or 2%NaOH test in 24hours-No Change | No Change |

| Coating Adhesion | ≥1grade for 10*10mm2 gridding test | 1grade |

| Peeling Strength | Average ≥5N/mm of 180oC peel off for panel with 0.21mm alu.skin | 9N/mm |

| Bending Strength | ≥100Mpa | 130Mpa |

| Bending Elastic Modulus | ≥2.0*104MPa | 2.0*104MPa |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Temperature Resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropped≤10% | Change of glossy only.No paint peel off |

| Hydrochloric Acid Resistance | No change | No change |

| Nitric Acid Resistance | No Abnormity ΔE≤5 | ΔE4.5 |

| Oil Resistance | No change | No change |

| Solvent Resistance | No base exposed | No base exposed |

Related PRODUCTS

-

Whatsapp

-

Whatsapp

WhatsApp

-

Top