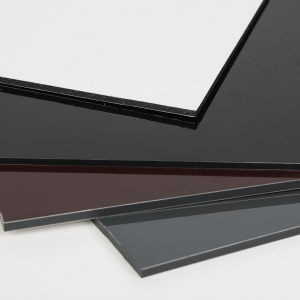

NEWCOBOND® 20 Years Warranty PVDF Metal ACP for External Wall Cladding

Practicality and cost-effectiveness are core strengths of these panels, starting with their ultra-lightweight design—only 1/3 the weight of solid metal sheets and 1/4 that of steel. This lightness simplifies transportation, lifting, and on-site handling, significantly reducing labor and logistical costs. They are also incredibly easy to process, enabling cutting, bending, folding, punching, or curving into elaborate shapes with minimal effort, while multiple installation methods (dry hanging, gluing, screwing) streamline construction workflows, shorten project timelines, and lower installation complexity. Maintenance is equally hassle-free: their stain-resistant, dirt-repellent surfaces can be kept clean with just water or a damp cloth, eliminating the need for frequent refinishing or costly replacements. As a cost-efficient alternative to solid metal panels, they deliver comparable performance at a more competitive price point, while their long service life and 100% recyclable aluminum core reduce long-term replacement costs and environmental impact, maximizing return on investment.

STRUCTURE

ADVANTAGES

ENVIRONMENTAL FRIENDLY

NEWCOBOND used recyclable PE materials that imported from Japan and Korea, composite them with pure AA1100 aluminum, it’s totally non-toxic and friendly to environment.

EASY PROCESSING

NEWCOBOND ACP has good strength and flexibility, it’s easy to transform, cut, fold,drill, curve and install them.

WEATHER-RESISTANT

Surface treatment with high-grade ultraviolet-resistant polyester paint (ECCA) request, guarantee 8-10 years; if use the KYNAR 500 PVDF paint, guaranteed 15-20 years.

OEM SERVICE

NEWCOBOND can supply OEM service, we can customize size and colors for clients. All RAL colors and PANTONE colors are available

DATA

| Aluminum Alloy | AA1100 |

| Aluminum Skin | 0.18-0.50mm |

| Panel Length | 2440mm 3050mm 4050mm 5000mm |

| Panel Width | 1220mm 1250mm 1500mm |

| Panel Thickness | 4mm 5mm 6mm |

| Surface treatment | PE / PVDF |

| Colors | All Pantone & Ral Standard Colors |

| Customization of size and color | Available |

| Item | Standard | Result |

| Coating Thickness | PE≥16um | 30um |

| Surface pencil hardness | ≥HB | ≥16H |

| Coating Flexibility | ≥3T | 3T |

| Color Difference | ∆E≤2.0 | ∆E<1.6 |

| Impact Resistance | 20Kg.cm impact -paint no split for panel | No Split |

| Abrasion Resistance | ≥5L/um | 5L/um |

| Chemical Resistance | 2%HCI or 2%NaOH test in 24hours-No Change | No Change |

| Coating Adhesion | ≥1grade for 10*10mm2 gridding test | 1grade |

| Peeling Strength | Average ≥5N/mm of 180oC peel off for panel with 0.21mm alu.skin | 9N/mm |

| Bending Strength | ≥100Mpa | 130Mpa |

| Bending Elastic Modulus | ≥2.0*104MPa | 2.0*104MPa |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Temperature Resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropped≤10% | Change of glossy only.No paint peel off |

| Hydrochloric Acid Resistance | No change | No change |

| Nitric Acid Resistance | No Abnormity ΔE≤5 | ΔE4.5 |

| Oil Resistance | No change | No change |

| Solvent Resistance | No base exposed | No base exposed |

Related PRODUCTS

-

Whatsapp

-

Whatsapp

WhatsApp

-

Top